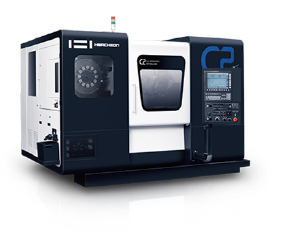

C2 Multiplex Turning Center

Videos

Specifications

C2 is an integrated multiplex turning center that combines the processing capability of a turning center with the processing capability of a machining center obtainable through Y and C-axis control. It is capable to manufacture parts in complex geometry with a single chucking and its standard-fitted automatic tool changer enables prompt machining of parts that require many tools

| Item | Unit | C2 YMC | C2 YSMC |

| Swing over Bed | mm (inch) | Ø730 | |

| Max Cutting Dia (Main / Sub) | mm (inch) | Ø630 (Ø24.8) | Ø630 / Ø510 (Ø24.8 / Ø20.08) |

| Max Cutting Dia (Main / Sub) – Parts Catcher option is required |

mm (inch) | Ø450 (Ø17.72) | Ø450 / Ø510 (Ø17.72 / Ø20.08) |

| Max Cutting Length (Main / Sub) | mm (inch) | 557 (21.93) | 557 / 569 (21.93 / 22.4) |

| Chuck Size (Main / Sub) | inch | 8 (OPT: 10) | 8 (OPT: 10) / 6 |

| Max Spindle Speed (Main / Sub) | rpm | 5,000 | 5,000 / 6,000 |

| Through Spindle Hole Diameter (Main / Sub) | mm (inch) | Ø76 (Ø2.99) | Ø76 (Ø2.99) / Ø38 (Ø1.5) |

| Spindle Motor (Main , Sub) | kW (HP) | 15 / 11 (20 / 15) | 15 / 11 (20 / 15) , 15 / 11 (20 / 15) |

| Number of Tool Station | ea | 18 | |

| Rapid Speed (X / Z / Y / B) | m/min (ipm) | 30 / 30 / 15 / 30 (1,181 / 1,181 / 591 / 1,181) | |

| Max Stroke (X / Z / Y / B) | mm (inch) | 360 / 700 / ±60 / 705 (14.17 / 27.56 / ±2.36 / 27.87) | |

| Turnmill Spindle Motor | kW (HP) | 5.5 / 3.7 (7.4 / 5) | |

| Floor Space (L x W x H) | mm (inch) | 3,610 x 2,784 x 2,360 (142.13 x 109.61 x 92.91) | |

| NC Controller | Fanuc 0i-TF | ||